From Idea to Reality: Low Fidelity Prototypes Lead the Way

Have you ever had a great idea for a product but weren’t sure how it would look or feel in real life? Maybe you have ten design variations for the same product and need to start narrowing them down. That’s where Low Fidelity Prototypes come into play!

These simple models help bring idea to life quickly and cheaply. Let’s dive into how to effectively utilize them, and why they’re so useful.

What are 'Looks-Like, Feels-Like' Prototypes?

Low fidelity prototypes, or ‘looks-like, feels-like’ prototypes, are simplified models of a product. Made using very simple materials like cardboard or foam, these lo-fi prototypes can give you an idea of what your device might look and feel like at the earliest stages of development. Think of them as a 3D sketch you can hold in your hands. It’s all about getting a sense of the size, shape, and how it might feel to use.

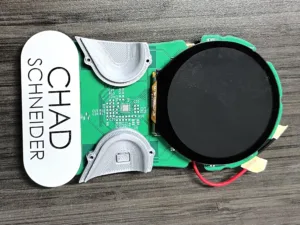

In contrast, a functional prototype may not look the part at all. It could be as unrefined as a set of motors on a bench, as long as it can perform the desired function.

What is the Strategic Value of Low Fidelity Prototypes?

So, why bother with these simple models? Some may see this as an extra step – a time waster – but we disagree. Successful product development should always start with low fidelity prototypes.

'Looks-Like' Prototypes in Action

Low Fidelity Prototypes for a Medical Device

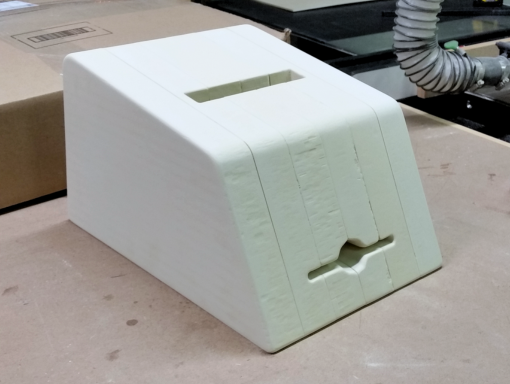

A medical device company came to us with their design already rendered in CAD. Before moving forward with expensive fabrication, they wanted to validate their design in the real world. So, they asked us to take their design for an enclosed diagnostic device with a tablet and tablet holder and create a ‘looks-like, feels-like’ prototype.

Since the overall goal of this project was to test the form and ergonomics of the design, it was important that we deliver an accurate representation of the design. We fabricated the prototypes with simple modeling foam, using laser cut templates to ensure precise dimensions and smooth cuts.

Then, we shaped, smoothed, and sanded the foam by hand, using Bondo to fill in the porous foam and help create a professionally polished appearance. Everything was finished off with a glossy white, leaving us with our cosmetic looks-like prototype.

The whole endeavor took less than a week, and provided our client with exactly the information they needed to move forward with their development. They were able to gather meaningful data on user reaction to the size, shape, and form of the mockup, which informed the next iteration of design.

Exploring an Automatic Golf Club Cleaner

A product company came to us with their idea for an automated golf club cleaner, but not much more than that. They were looking to get a better idea of what it would take to bring this idea to life, so we set out to brainstorm concepts and start building.

With so few guardrails on the project, we were wide open to go in any direction we wanted. While that’s always an exciting challenge for our engineers, it can present a daunting reality – when you have every option available, how do you narrow down which direction to go?

That’s the real benefit of using low fidelity prototypes! We were able to quickly test, toss, and iterate on multiple different ideas without sinking big money into more detailed engineering.

We started with the most simple of materials – humble cardboard. This was the easiest way to put together many variations on the design, testing different orientations, angles, and sizing. It was much easier to play around with different door and hinge placements, for example, with cardboard mock-ups in hand rather than having to painstakingly build out each design idea in CAD.

Being able to use actual golf clubs in our shop against these cardboard mock-ups allowed us to quickly and easily rule out any designs that clearly wouldn’t work out. We were able to play around with where and how to install the motors, and test out different layouts for scrubbers. Then, we worked with the client to refine the design based on what worked and what didn’t before we jumped to the digital world for a 3D Printed version of our cardboard prototype.

Our finalized design was 3D Printed to verify that everything would fit together and work how intended before moving onto things like material selection and fabrication. And you can definitely see how the cardboard mock up on the left evolved into our 3D Printed prototype!

Going through this trial and error process helped us refine the best design before we started making more detailed computer models. Taking the time to do this up front saved our client time and money by helping us sort out what worked (and what didn’t) early on.

The 'Looks-Like, Feels-Like' Approach

So, now you know that you should be using low fidelity prototypes, but what about when? They’re most helpful for validating big ideas in the earliest stages, especially if you’re looking to save on engineering costs. And the feedback from potential users from the very beginning is invaluable!

Focus on Form Factor & Ergonomics

The real value is in seeing how your product looks and feels. Pay close attention to size, shape, and how comfortable it is to use. This data will help you figure out what works best before getting into all the messy, expensive technical details.

Rapid Iteration & Design Refinement

One of the best things about low fidelity prototypes is how quick they are to make and change! Don’t like how something came out? No problem, we can tweak it and have a totally new design ready in no time.

Materials & Techniques for Low Fidelity Prototypes

You can use all kinds of materials to make these ‘looks-like’ models. Foam, cardboard, and various craft materials are easily accessible for everyone. Simple 3D printed parts can even slightly elevate the look, but it doesn’t matter what you use as long as it can effectively communicate your idea.

Gathering User Feedback

User feedback is gold at every stage of design – it helps us make the next iteration of the product even better. Once we have a physical prototype, we can put it in people’s hands and see what they think. How do they hold it? Interact with it? Do they like it or hate it?

Transitioning from 'Looks-Like' to Functional

Now that you’ve made some low fidelity prototypes, tested them out, and gotten some great feedback – what’s next? It’s time to take all that data and start moving towards a functional product!

With a clear direction to go with your device, it’s time to get into the engineering. You can take what you learned from your ‘looks-like’ prototype and start figuring out how to make it functional. This is where things will start to get a bit more technical, and a lot more involved.

Consult One of Our Expert Engineers Today!

Working through a medical device development process can be complex and difficult work – we know that better than most! Let us help you navigate the tricky path through regulations, design, testing, manufacturing, and beyond. You don’t have to go it alone!

Learn from your Low Fidelity Prototypes

Put that all-important feedback you got from your ‘looks-like’ prototype to good use! As you put together the next iteration of your design, make sure you’re addressing any feedback that came up during this phase.

Did people like the size? If it was too big or too small, now’s the time to make adjustments. Maybe the screen angle needs to be shifted, or certain buttons need to be bigger. And, of course, make sure to keep the good stuff in! If there were features that performed well in testing, make sure they make it into the next version.

By using what you learned from your low fidelity prototypes, you’re giving your product a head start. You’re not just guessing what people might like – you already have the data.

Accelerate your Development with 'Looks-Like' Prototypes!

Low fidelity prototypes may seem simple, but they’re a powerful tool for medical device development. They help you see and hold your ideas in real life, get early feedback, and make smart choices about your product’s design.

Whether you’re working on a medical device, golf gadget, or anything in between, start with a ‘looks-like’ prototype! This simple step can save you time, money, and headaches down the line. It’s all about bringing your ideas to life, one simple model at a time!