ATI had asked us to investigate better test methods for disposable N95 respirators that could be used with their 100X Automated Filter Tester. We answered the following questions and performed the engineering, prototype fabrication, and testing of a new fixture for the process.

- What materials could be an alternative to beeswax for N95 mask testing?

- What other system components would be required to create this mask test fixture?

- Do any of the sealing materials pair better with a disposable insert sheet?

- What materials are preferred for such a disposable insert?

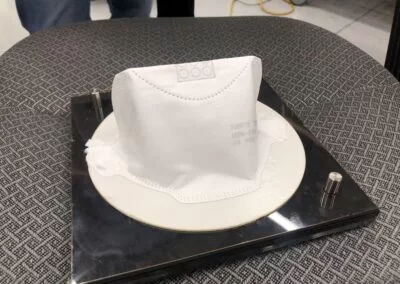

Air Techniques International (ATI) produces their 100X Automated Filter Tester. It is generally used by customers to test 2-dimensional material samples to validate their filtration performance as part of their manufacturing process. Aerosolized particles of a specific size are introduced by the Tester on the inlet side of the filter material and the outlet is measured to determine filter performance. Some of their customers wanted to test their filters following manufacturing on products such as N95 masks. To do so required a fixturing system to adequately capture and seal the N95 respirator to separate the inlet and outlet sides of the mask.

The NIOSH test method used to validate respirators to the N95 standard uses beeswax to bond the edge of the mask to a flat plastic sheet before installing it into a device similar to the 100X Filter Tester. Beeswax is selected because it has no noticeable outgassing to contaminate the particle measurement. This is especially important for HEPA filter testing, which must eliminate 99.97% of airborne particles, but may not be a factor for N95 masks, which must only filter 95% of particles.

Highlights

DESIGN FOCUS

- Seal well

- Little outgassing

- Does not require clamping

- Does not require heating/melting/significant preparation for use

- Compare hardening to non-hardening materials

- Cleanable

FABRICATION

- Adhesive selection

- Material selection

- Machined Acrylic