Design for Manufacturability with a Pharmaceutical Flavoring Device

In the world of pediatric medicine, making medications more palatable for children has always posed a significant challenge. Our customer developed an innovative solution: a way to reconstitute medications and add in child-friendly flavors.

Their automated dispensers do all of the mixing for you at the push of a few buttons. And, these devices connect directly to pharmacy water lines, ensuring adherence to strict water quality requirements.

This company stood behind their product, and looked for a continual process to improve the device and resolve concerns that naturally arise in a first iteration. Our team was tasked with investigating the root cause of identified areas for improvement, and putting together possible solutions – something our team is particularly skilled at.

Dan Connor

Technical Director, FLAVORx

“We’ve worked with the Root3 Labs team on several projects over the last few years and have always been impressed with their quick response, in depth subject knowledge, and ability to take end user feedback and make product changes that are effective. Root3 Labs has worked on exciting new products for us as well as existing products in need of modifications and or design reviews. All of our design reviews have been well thought out, in depth, using the latest analyzing equipment to indicate weak points in the current iterations.

When it comes to modifications to existing products, the Root3 Labs team gets to work fast! They understand that when something in the field isn’t working right, waiting to fix it just isn’t an option for the end customer. They collect all historical data, product samples and discuss the desired end result.

Where they excel is coming up with unique pathways to achieve that desired end result that are logistically feasible, cost effective and that work! We’ve had electrical, mechanical, software engineering requests of Root3 Labs over the years and their team’s backgrounds are diverse enough to handle all of these different scopes. I would have no hesitation in recommending Root3 Labs to any of my colleagues for their design needs.”

The Challenge: Design Innovation Meets Manufacturing Reality

The challenge for us would lay in not only identifying the source of any areas needing improvement, but also keeping Design for Manufacturability principles in mind when proposing any solutions. Since these devices were already being manufactured, any changes made to the design would then have to be produced on a large scale. We would have to keep all those end stage requirements in mind when making suggestions.

Tip: Design for Manufacturability (DFM) is crucial in medical device production! DFM is the practice of considering the end-stage manufacturing processes during the initial design phase to ensure efficient, cost-effective production without compromising on product quality or functionality. At every stage of design, you should be considering how your device might be manufactured – it can effect everything from your CAD models to your material selections! The last thing any designer or engineer wants is to be sent back to square one over a manufacturing mismatch at the end of an already long development cycle.

Tip: Design for Manufacturability (DFM) is crucial in medical device production! DFM is the practice of considering the end-stage manufacturing processes during the initial design phase to ensure efficient, cost-effective production without compromising on product quality or functionality. At every stage of design, you should be considering how your device might be manufactured – it can impact everything from your CAD models to your material selections! The last thing any designer or engineer wants is to be sent back to square one over a manufacturing mismatch at the end of an already long development cycle.

Initial Investigation and Digging Deeper

Design Review and Stress Testing

Our first step was to do a comprehensive Design Review. We started with the theory that too much stress was being placed on certain parts, leading to the cracking and leaking.

A Design Review is the best way to get up to speed quickly and understand what we’ll be working with. Since this dispenser was already a manufactured device, we had some catching up to do to understand the original engineering behind it and how we could improve it. Here’s what went into our Design Review:

- We thoroughly examined every function, facet, input, and output of the device. We did this both in the digital design, and on a physical test unit.

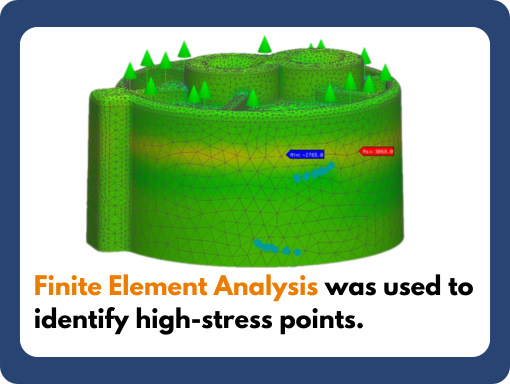

- We performed Finite Element Analysis (FEA) on CAD models to identify potential high-stress points.

FEA allowed us to analyze the device under static load, so we could determine if the load on the materials was within tolerable thresholds. We would need to rule out other factors that could cause problems, including:

- Excess pressure from the pressurized system

- Humidity variations

- Temperature fluctuations

- Vibrations during operation

However, because of our detailed Design Review, we were able to rule out these other factors. The overall Design Review and the FEA work was crucial to inform how our proposed changes would improve the device. With the most obvious potential causes ruled out, we needed to start investigating what else might be a factor.

Broadening the Investigation

To delve deeper, we conducted Chemical Compatibility Testing on samples of the flavorants and plastic materials. First, we referenced data sheets online – there are plenty out there that have already been compiled for you. You simply need to cross-reference your base chemical and material! We were able to save some time that way, but it would still be important to run our own experiments and record our own observations, as well.

It’s not uncommon to have a mismatch between various foods we eat and plastic materials. Polycarbonate is a durable, clear material that’s great for protecting your eyes as sunglasses, or creating bulletproof glass. But, you won’t often find it as a container for fruit juices because juice can quickly degrade the material and cause fine cracks.

For our hands-on experimental Chemical Compatibility Testing, we performed soak tests with the material samples submerged in the flavorants for long periods of time. During those soaking periods, we would diligently record our observations, noting any changes in the materials. These experiments showed that the pressurized system would cause tube expansion, leading to the barb fittings leaking.

All of this testing showed that we needed to find a replacement material that would function better within the pressurized system.

Some of these soak tests lasted over two months!

Material Selection for Design for Manufacturability

Chemical Tolerance vs Strength

With various root causes identified, our challenge shifted to finding the right alternative materials. Any new materials we recommended would need to be chemically compatible with the flavorants and still maintain the necessary strength and size parameters for manufacturing.

This challenging balancing act is exactly why material selection is so critical to Design for Manufacturability. We needed to keep multiple considerations in mind, like:

- Chemical compatibility with the flavorants

- Structural integrity that could stand up to the pressurized system

- Compatibility with the existing manufacturing processes and tolerances

Addressing Molding Constraints

As we looked into alternative material options, we ran into another critical DFM consideration: molding constraints for injection molding.

Different plastic materials have different processing parameters for molding, such as temperature requirements, pressure tolerances, and shrink factors. Temperature and pressure is easy to adjust, but the shrink rates can complicate things. If the new material didn’t shrink at the same rate as the original, the final dimensions would be wrong, leading to ill-fitting parts.

We could have gone with a new mold to compensate for the difference in shrinkage, but it would be a large extra expense. The ideal solution would be to keep the same molds and simply swap in a new material.

Although the new material we selected didn’t have the same shrink rate as the original material, we figured out that adding a filler material could fix both the shrink factor and material strength. We worked closely with the molding company, running multiple test batches with varying parameters and filler ratios. Through this iterative process, we eventually developed an optimal “recipe” that achieved all of our client’s manufacturing goals without requiring expensive new molds.

Continuous Improvement in Design for Manufacturability

Our work with this customer didn’t stop at solving the immediate issue. We were happy to be able to continue working together on further design refinements, always with DFM principles in mind.

Some key improvements included:

- Noise Reduction: We redesigned components to minimize operational noise, enhancing the user experience.

- Assembly Optimization: We were able to improve the barb fittings and tubing connections, making them easier to assemble and more reliably leak-proof.

- Electronic Enhancements: We used Root Cause Analysis of a malfunctioning SD card reader, improving the device’s reliability.

- Functional Upgrades: We identified and tested a new over-pressure valve for more accurate activation.

The Power of Design for Manufacturability

We think our work on this project highlights the critical importance of Design for Manufacturability in medical device production. By thoroughly addressing material selection, molding constraints, and ongoing iterative design refinements, we have been able to help the team meet their goal of a reliable, efficiently manufactured device.

Our strongest takeaway from this project is not to underestimate the long-term benefits of applying DFM principles throughout the entire development process. The world of MedTech is always evolving, but you can use the principles of DFM to guide you through turning your innovative ideas into reliable products that improve lives.

Working through a medical device development process can be complex and difficult work – we know that better than most! Let us help you navigate the tricky path through regulations, design, testing, manufacturing, and beyond. You don’t have to go it alone!

Consult One of Our Expert Engineers Today!

Highlights

DESIGN FOCUS

- Material Selection

- Design for Manufacturability

- Fluid Dynamics

FABRICATION

- Injection Molding

- Material Selection for Manufacturing

- Chemical Compatibility