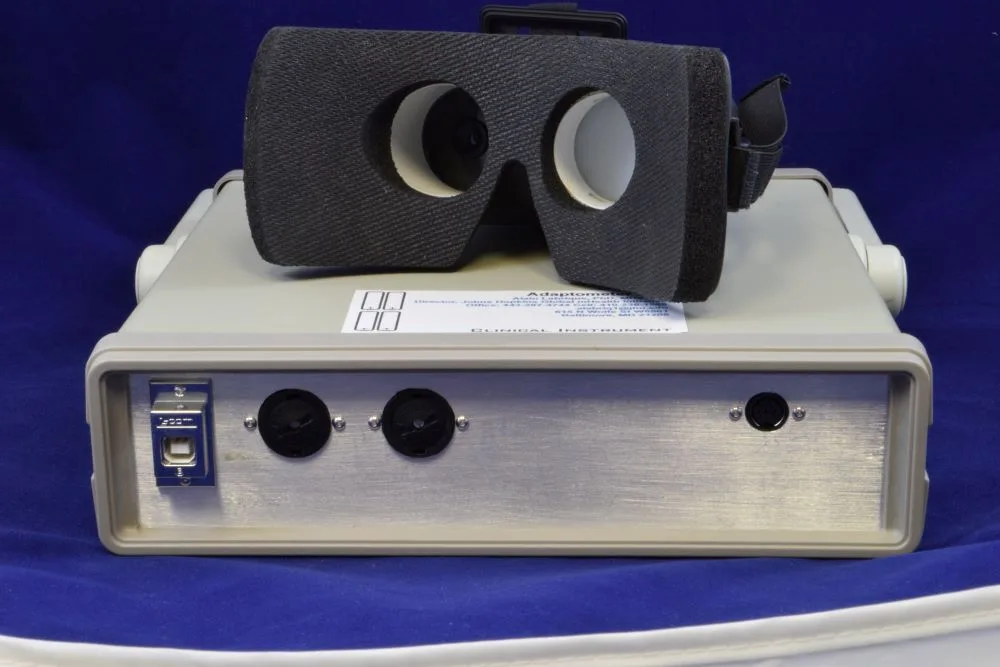

Goggles for Diagnosing Eye Diseases

The Problem:

Unusual dark adaptation, such as pupilary response, is commonly associated with numerous ocular diseases, so the procedure serves as an objective diagnostic tool, but it can be difficult to administer well in low-resource settings. Researchers at a Baltimore research hospital had developed a “dark field adaptometer” to measure pupilary response in low-resource settings through the use of goggles to restrict environmental light and allow the repeatable measurements to occur regardless of the external lighting conditions or local facilities. Over time, the devices wore out from use and the original components had largely become obsolete. The researchers needed more prototype devices to support their field testing and clinical work, so they came to Root3 Labs to update their design and provide low-volume prototype fabrication and testing of all the components.

Updating the Design

The Solution:

We picked through the electronics Bill of Materials to figure out which components needed to be updated and how the circuit needed to be updated. In addition to the optical camera, lens, and lighting components, we also had to adapt the computer vision software originally written for WindowsXP. With the design detailed and ready for fabrication, we built the PCBs, cast the rubberized goggles, cut foam gaskets for the user’s face, and hand-sewed the straps. Then we built the electronics control box and tested everything to ensure proper functionality and calibration.

Project Highlights

DESIGN FOCUS

- Component & Design Updates

- Software Modernization

- Hardware Ruggedization

- Embedded Electronics

- Design for Manufacturing

FABRICATION

- Material Selection

- Rubber Casting

- CNC Machining

- Electronics Assembly