Industrial Design

From One Problem to Multiple Solutions

We don't just design what you ask for - we explore what's possible. Our Industrial Design process uncovers the best path forward, not just the obvious one.

You're here because you know what problem you need to solve, but you're not sure about the best approach. That's exactly where Phase 1 shines - we take your requirements and explore multiple directions to find the optimal solution.

Why Our Industrial Design Approach Works

Most design firms give you what you ask for. We give you what you didn’t know was possible. Our team approaches every project with fresh eyes, challenging assumptions and exploring alternatives you might not have considered.

We’re not just making things that look good, and we’re not fulfilling a basic order – we’re solving complex problems through thoughtful industrial design that considers manufacturability, user experience, and technical constraints from day one.

Explore How We Can Help Guide Your Concept Generation Journey:

From Sketches to Solutions

Step 1: Requirements Deep-Dive

We start by understanding what you’re looking for and why you want it. What are the real constraints? Who’s the end user? What does success look like for your project?

Step 2: Concept Generation

This is where the magic happens! We generate multiple design directions – sometimes dozens of concepts – exploring different approaches to your challenge.

Step 3: Concept Evaluation

We work with you to evaluate concepts against your criteria, diving deep into technical feasibility, manufacturing requirements, user needs, and business goals.

Step 4: Concept Refinement

The winning concept gets refined and detailed, preparing it for the next phase of development – functional prototyping to test concept feasibility in the real world.

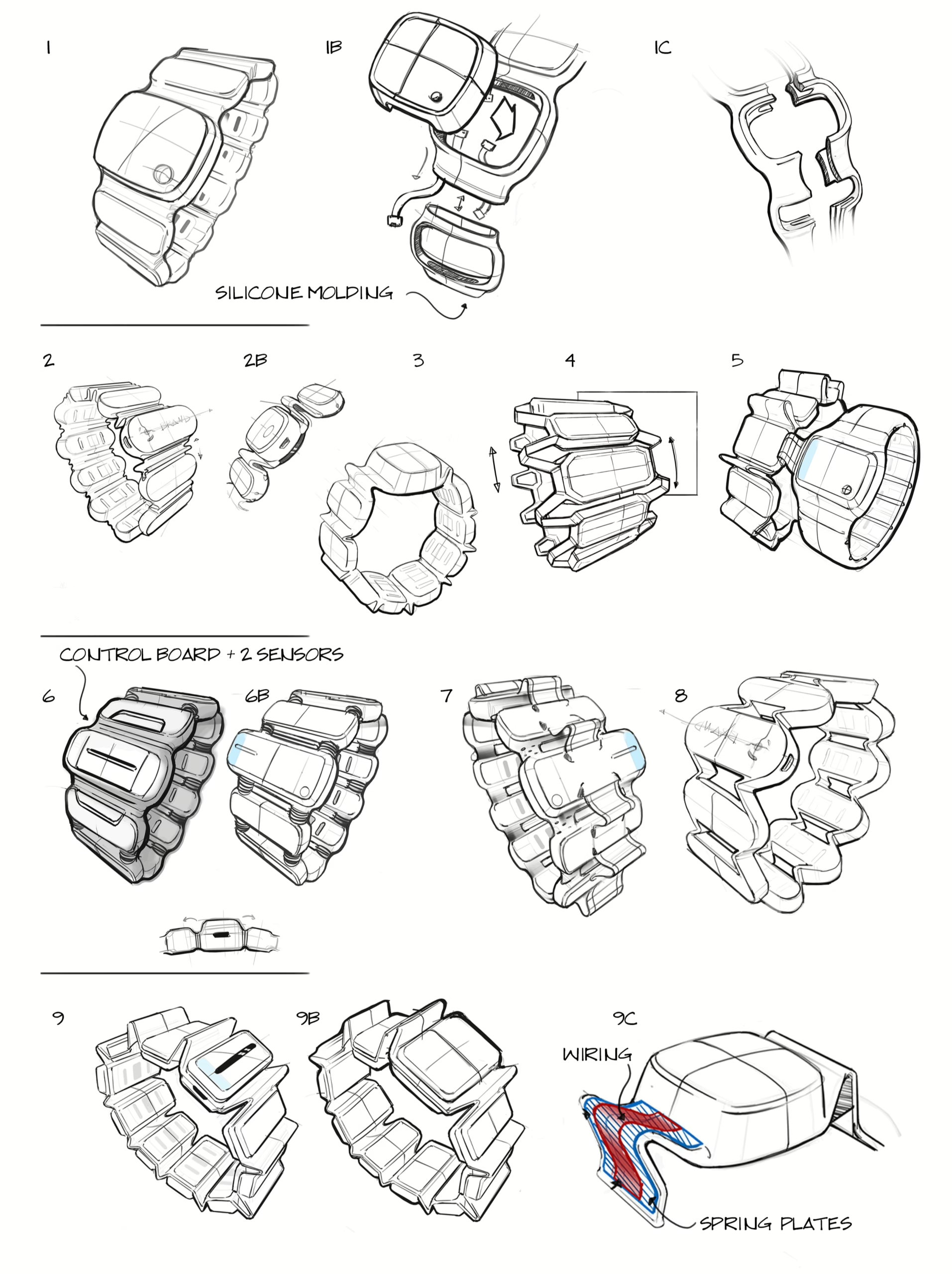

Biomedical Armband Concept Generation

The Challenge

When our client needed an ‘impossible’ wearable sensor, we knew it was our kind of challenge. The ‘impossible’? A wearable armband sensor that could accommodate different arm sizes while maintaining precise electrode contact for muscle signal detection. In other words, an ‘impossible’ design puzzle with competing technical requirements.

Our Approach

With no obvious solution, we explored multiple design directions for the armband. Our concept sheets included rigid segmented designs, flexible continuous materials, multiple shapes and sizes, and even hybrid approaches.

Working closely with the client’s team, we were able to review and refine until we ended up with the winning concept – a segmented design with flexible interconnects to solve the uniform expansion while also protecting the internal electronics and sensors.

What Industrial Design Looks Like at Root3 Labs

Concept Exploration & Sketching

- Multiple design directions from a single brief (8-15 concepts)

- Hand sketches and digital concept development

- Form factor exploration and user interaction mapping

Design for Reality

- Manufacturability considerations built into every concept

- Evaluation for material selection and production method

- Cost-conscious design decisions

Technical Integration

- Mechanical constraints and assembly considerations

- Designed for electronics housing and thermal management

- Regulatory and safety requirements integration

Iterative Refinement

- Rapid concept testing and validation

- Design evolution based on feedback and constraints

- Collaborative refinement on concepts with your team

Industry Expertise

Medical Devices:

When it comes to medical devices, lives are literally on the line. That’s why our team takes a rigorous and patient-focused approach to design. Throughout the entire process, our goal is to design a safe and effective medical device that will improve patient outcomes. With our extensive in-house prototyping capabilities, we deliver solutions that meet stringent deadlines and perform under pressure.

Defense Systems:

At Root3 Labs, we’ve been supporting defense and government clients since 2014, developing mission-critical hardware that performs reliably in the most demanding environments. Our engineering team has helped US ARMY, DHS, and NSF clients transform their innovative concepts into field-tested prototypes through our proven approach that combines mechanical, electrical, and software expertise.

Ready to Explore Your Options?

Whether you have a specific industrial design challenge or want to see how our concept generation process could help your project, we’re here to help.