Medical Device Design Services for Improved Patient Outcomes

At Root3 Labs, our mission goes beyond building functional medical devices; we create life-saving solutions that prioritize patient safety, usability, and regulatory compliance.

Our comprehensive, detail-oriented approach ensures each design phase delivers on reliability and ease of use, providing devices that are intuitive for users and safe for patients.

From early prototyping to rigorous testing and detailed documentation, we partner with you every step of the way. Discover how our process translates complex medical needs into effective, market-ready solutions designed to enhance patient care and outcomes.

Download Your Guide to Product Development

Key Factors for Reducing Risk During Product Development

The Root3 Labs Difference

Here at Root3 Labs, we follow a First Principles process of breaking down obstacles into their most fundamental pieces. Then we get to work with the next step: Designing, Prototyping, & Testing solutions iteratively before putting it all back together.

We look at design details thoughtfully from every perspective, ensuring it all interacts smoothly. We look at the material selection, manufacturing cost, assembly, user experience, and more – which ultimately leads to a quality, successful product.

Our extensive on-site workshop allows our engineers to fabricate many of our prototypes in-house, then quickly iterate & refine them rather than be delayed by unnecessary vendor lead times.

Every project is customized to meet your needs. We can provide either Fixed Price or Time & Materials proposals that layout the Project Plan and define the Scope of Work.

Explore Our Successful Medical Device Projects

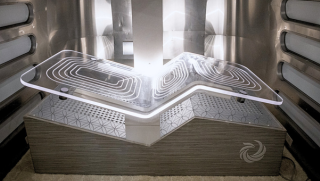

Wellness Product Engineering

The Ammortal Chamber is an immersive experience that guides the user through physical, mental, and spiritual rejuvenation. It blends sound, light, vibration, an electrical field, meditation, molecular hydrogen, and breath work.

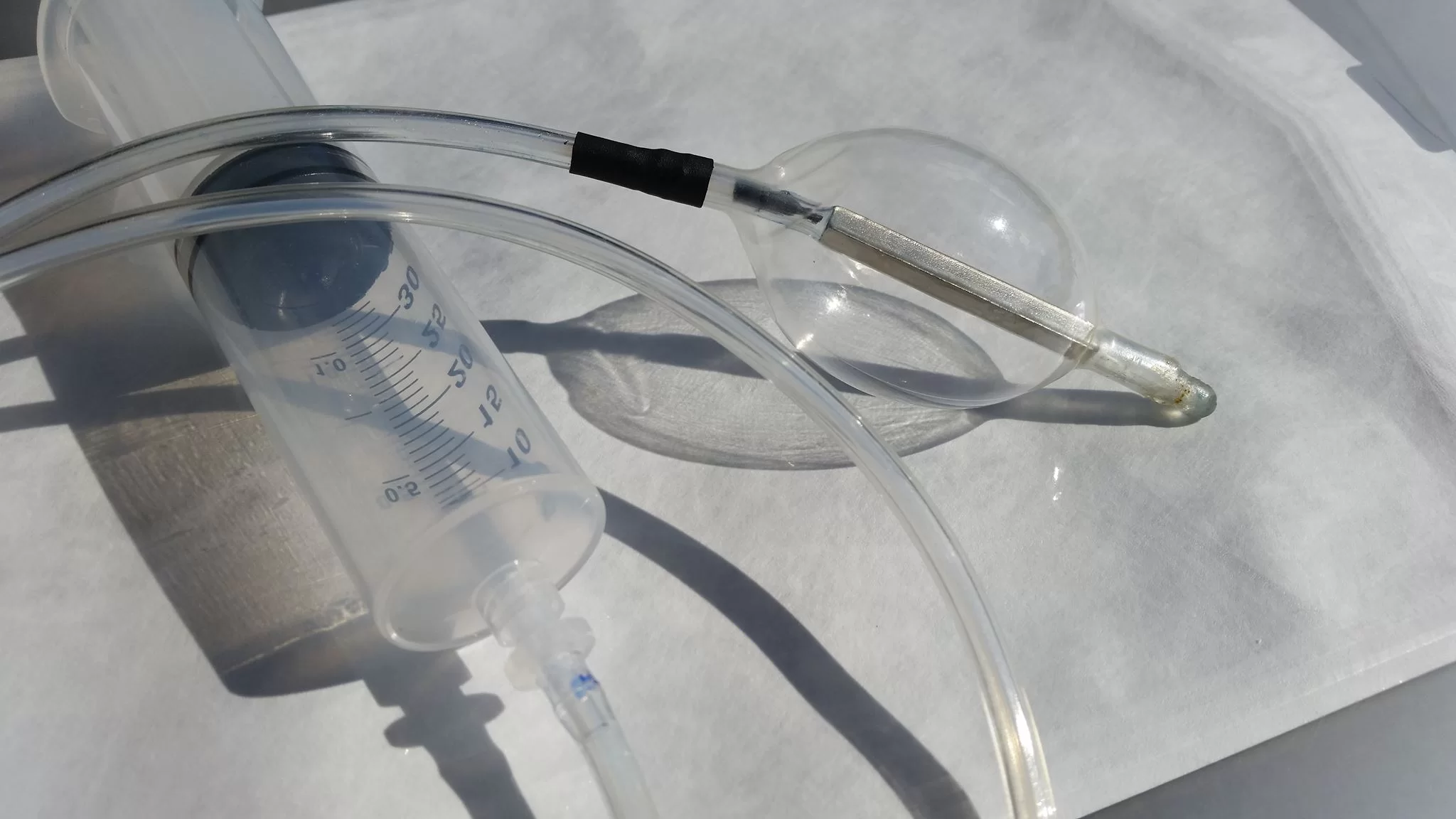

Coaptive Ultrasound Gastrostomy

We were able to support this project to develop a novel method of CUG that could be performed bedside from the earliest concept phase all the way through to manufacturing and regulatory approval.

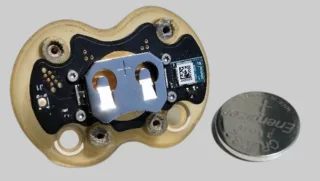

Smart Pacifier

We worked with Brainchild Technologies, LLC, to develop a smart pacifier that uses embedded sensors to monitor the suckling behavior of newborn babies. The pacifier communicates intensity and frequency data to a fellow Bluetooth enabled device in real-time.

Medical Device Design: From Concept to FDA Approval

Comprehensive Design and Documentation for FDA Approval

When it comes to medical devices, lives are literally on the line. That’s why our team takes a rigorous and patient-focused approach to design.

We start by looking at usability and ergonomics, tailoring our design so users will be able to operate the device easily, correctly and safely. We also analyze potential risks, finding ways to maximize reliability and minimize the chance of errors. Finally, we help our customers prepare for the FDA regulatory process, making sure that all the necessary testing, documentation, and submission materials are in order.

Throughout the entire process, our goal is to design a safe and effective medical device that will improve patient outcomes.

Prototyping from Bench to Bedside

- Initial benchtop testing with simulated materials

- Advanced prototypes for cadaver studies

- Sophisticated designs for animal trials

Learn More

At Root3 Labs, we understand that the success of your product hinges on how well it is designed and manufactured. That’s why we take a comprehensive approach to medical device design, focusing on minimizing risk throughout the development process and not just as an afterthought.

Initial prototypes only need to work well on the benchtop and could be tested with materials to simulate tissue or bone. Slightly more advanced prototypes might support a cadaver study to demonstrate suitability and gather user feedback. For those devices that require live patient data, sophisticated prototypes can often support animal studies with special attention to bio-compatibility, reliability, and safety to ensure the ethical treatment of those animals.

Comprehensive Validation & Testing

- Laboratory testing & performance validation

- Real-world usage simulations

- FDA compliance verification

Learn More

Medical device design validation is the process of testing and documenting that the final product meets all the Device Product Requirements. It is an essential step in the product development cycle, as it helps to ensure that the device is safe and effective for patients, meets all performance goals, and satisfies regulatory requirements (among so many other requirements).

There are several methods of validation, including laboratory testing and patient or animal studies. Benchtop testing is used to validate that the device meets requirements such as environmental conditions, drop tests, shock & vibration, etc. Patient or animal studies are used to evaluate the safety and efficacy of the device in a real-world setting.

Both methods are essential for ensuring that a medical device is safe and effective for patients. Root3 Labs has extensive experience in the testing and validation process for medical devices and has helped numerous clients navigate the prototyping process toward FDA approval.

Quality Assurance & Documentation

- Complete Design History File management

- Manufacturing plan development

- Regulatory compliance documentation

Learn More

Medical device design documentation is critical to ensuring the quality and safety of devices. Each phase of the design process must be properly documented to show that all requirements are met and that the devices can be manufactured to meet regulatory standards.

We can help put together and manage the Design History File to capture the essential information about the device, such as the Design Specifications, Design Documentation, Manufacturing Package, Risk Analyses, and validation data.

The Manufacturing Package contains drawings, a Bill of Materials, and instructions necessary to manufacture the device and ensure quality. Finally, the regulatory approval process ensures that the device meets all relevant safety standards.

Expert Engineers Give Expert Advice

Have more questions? We have the answers!

Consult with one of our expert engineers to discuss your project, answer some questions, and see if we can help. No commitment necessary – tell us about your latest project!